Thanks to its focused and very qualified on-internet site R&D groups and particular pilot workshops, Unither has the know-how, gear and skills to deal with product or service advancement in the earliest stages.

As a way to take a look at these Organic products it was required to have a facility that would permit enhancement of Protected product packaging. maropack (Zell, Switzerland) put in the first neat-BFS-technology into a BSL-two rated facility to provide a place to fill and package deal all distinctive form of Organic merchandise.

Blow: A plastic tube is extruded and cut into personal units. 1 conclusion of each and every unit is sealed when the other finish remains open up.

The efficiency of BFS allows for both of those substantial and small orders being fulfilled with dependable excellent at large speeds and volumes. The aseptic BFS filling method enables just one device to conduct a steady sequence of automated functions to mildew plastic containers outside of molten resin (LDPE in ApiJect’s case), fill the containers with sterile liquid, then interesting and seal them in under three seconds.

Moreover, the filling zone is inaccessible to operators through equipment Procedure, even more improving the aseptic character of the process. In each BFS rotary and shuttle devices, the filling zone is in just an ISO 5 setting, guaranteeing a managed and sterile ecosystem.

Shim sets for all air knives are utilized to regulate the air hole which enhance or decrease drive and move

BFS producing is anticipated to practical experience an yearly advancement price of 8% concerning 2019 and 2029. The growth will probably be attributed to pharmaceutical providers, along with other emerging therapy markets, for instance biologics, which are conducting compatibility and steadiness tests with large molecule merchandise.

We provide you with an In general principle for qualification and validation identified because of the authorities all over the world.

This methodical approach to container formation underpins the reliability and sterility of the packaging approach, making certain here the security and efficacy with the goods it houses.

We use cookies to provide you with the ideal experience. By continuing to employ this site you consent to the use of cookies, Except if disabled from the browser. OkPrivacy coverage

The entire system occurs within an enclosed, sterile setting to forestall microbial and particulate contamination.

Technical scientific operate and surveys conducted in cooperation with universities and member Organizations.

The market is held to a similar standards, as all drug packaging technologies are, to make sure solution security and good get more info quality.

In case the container is somebody container such as a bottle, deep Mastering computerized inspection is likely for being extra helpful. For any strip of 5 or ten ampoules with a card joined with each other, automated inspection would continue to be a problem.

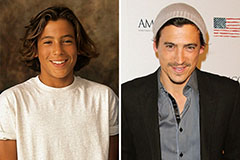

Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Mackenzie Rosman Then & Now!

Mackenzie Rosman Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now!